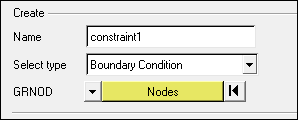

RD-T: 3500 Tensile Test Setup

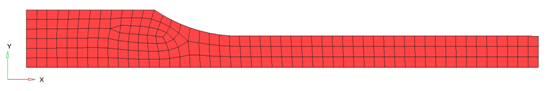

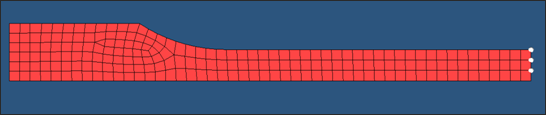

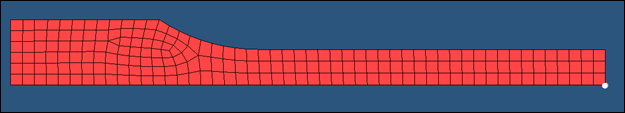

This tutorial demonstrates how to simulate a uniaxial tensile test using a quarter size mesh with symmetric boundary conditions.

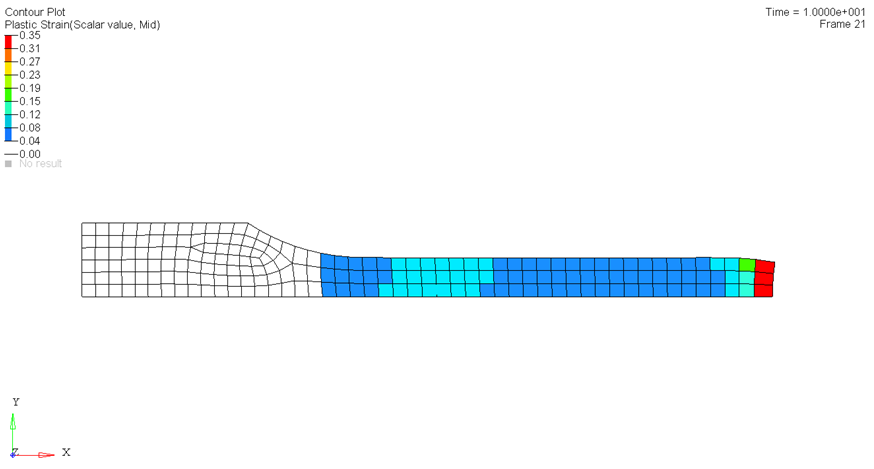

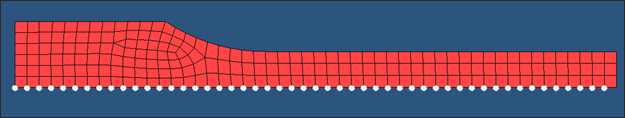

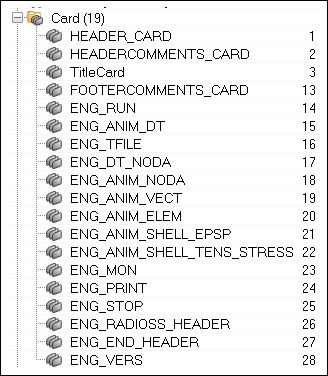

Figure 1.

Model Description

- UNITS: Length (mm), Time (ms), Mass (kg), Force (kN) and Stress (GPa)

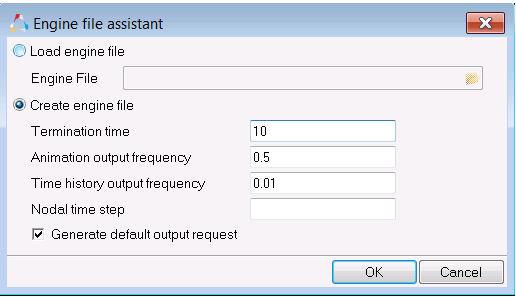

- Simulation time Rootname_0000.rad[0 - 10.]

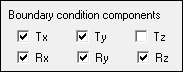

- Boundary Conditions:

- The 3 upper right nodes (TX, RY, and RZ)

- The center node on left is totally fixed (TX, TY, Rx, RY, and RZ)

- A symmetry boundary condition on all bottom nodes (TY, Rx, and RZ)

- At the left side is applied a constant velocity = 1 mm/ms on -X direction.

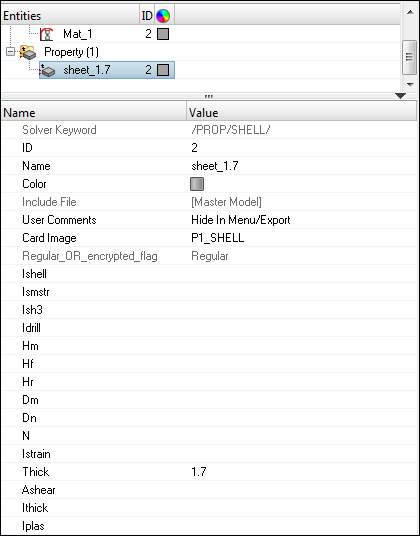

- Tensile test object dimensions = 11 x 100 with a uniform thickness = 1.7 mm

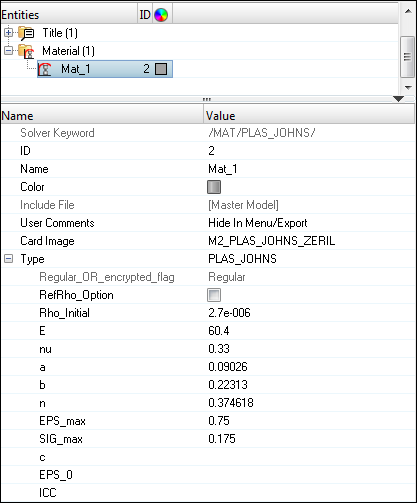

Johnson-Cook elastic plastic material /MAT/PLAS_JOHNS (Aluminum 6063 T7)

[Rho_I] Initial density = 2.7e-6Kg/mm3

[E] Young's modulus = 60.4 GPa

[nu] Poisson's ratio = 0.33

[a] Yield Stress = 0.09026 GPa

[b] Hardening Parameter = 0.22313 GPa

[n] Hardening Exponent = 0.374618

[SIG_max] Maximum Stress = 0.175 GPa

[EPS_max] Failure Plastic Strain = 0.75

Input file for this tutorial: TENSILE_000.rad

Import the Model

-

Click or click

.

.

-

Click the icon

to open the TENSILE_0000.rad file you saved to your working directory from the

radioss.zip file.

to open the TENSILE_0000.rad file you saved to your working directory from the

radioss.zip file.

- Click Open.

- Click Import.

- Click Close to close the window.

Create the Material

Create the Property

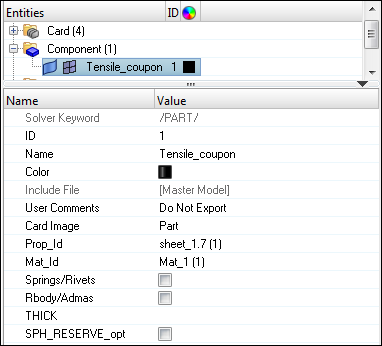

Assign the Material and Property

Create the Boundary Conditions

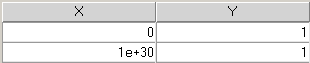

Create the Imposed Velocity

Create Output Requests

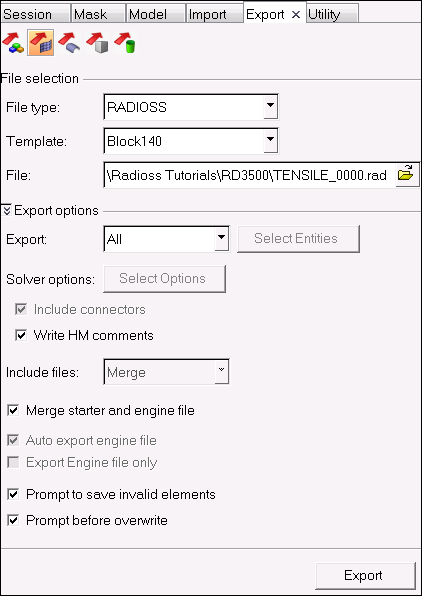

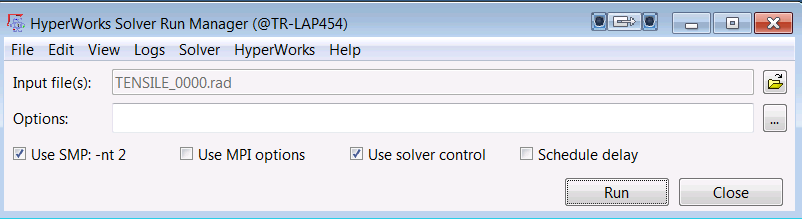

Export the Model

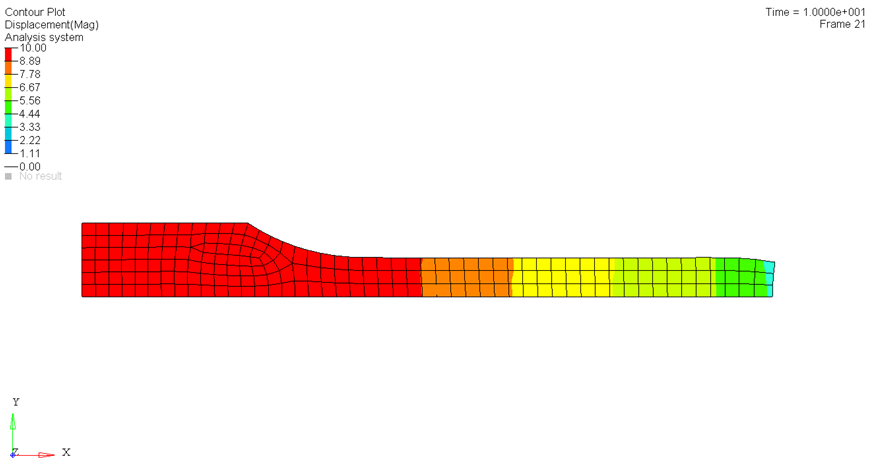

Expected Results

Figure 16. Total Displacement Contour (mm)

Figure 17. Plastic Strain Contour

.

.