3D to 2D/3D Element Mapping

3D linear or quadratic source element data can be mapped to 2D/3D target elements. 3D source elements can have loads or results which can be mapped.

-

Import or open a 3D/2D target model.

You can import a 3D model from solver files (current model), or results files containing temperatures, pressures, or other loads. When importing, use ID offset in order to preserve the new model's IDs.

-

Create and define a field entity.

- In the Model Browser, right-click and select Create > Field from the menu.

-

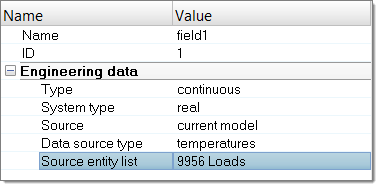

In the Entity Editor, define the current model

using loads or results.

Figure 1.

- Delete the source model.

-

Realize the field:

- In the Model Browser, right-click and select Realize from the menu.

-

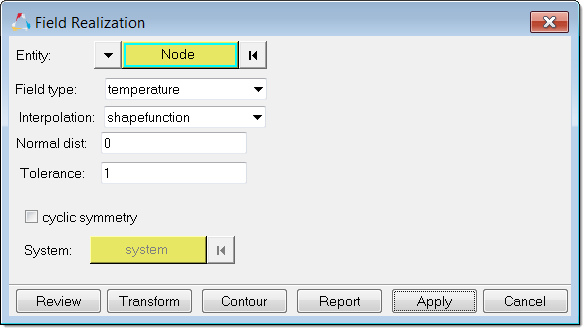

In the Field Realization dialog, define the

realization settings.

Figure 2. - Click Apply.

-

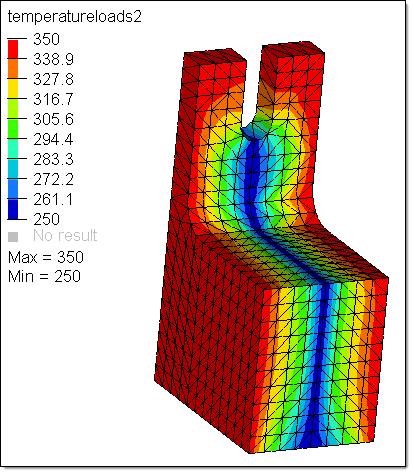

Click Contour to contour the target elements of a mapped

temperature load from another 3D source model.

Figure 3.