Fatigue Input/Output

Fatigue input for Spot Weld Fatigue Analysis can be divided into the following categories:

Fatigue Element Identification

- The spot welds (CBAR, CWELD, CBEAM) are referenced with the connected sheets as groups. These groups are currently referenced through components.

- The spot weld diameter, which is a function of the minimum shell element thickness, should be input in the Assign Material dialog.

- The result file should contain the shell thickness output to be automatically referred to the HyperLife Assign Material tool.

- CHEXA elements

can be used to define the weld element for Spot

Weld Fatigue Analysis. In such cases, the grid

point forces are resolved into corresponding

forces and moments at the face centers of the

opposing faces connected to the shells. The faces

of the CHEXA element attached

to the sheets should always consist of grid points

in the following order.

Figure 1. Faces of the CHEXA that Should be Used as Connection Faces with Shells for Spot Weld Fatigue

Additionally, the default weld element diameter of the CHEXA element for spot weld fatigue is equal to two times the smallest distance from the attachment face centroid to the edges.

Fatigue Parameters (Spot Weld Fatigue Dialog)

Figure 2.

- The RUPP method is currently applied to calculate the spot weld fatigue analysis.

- The spot weld fatigue parameters are applied in this dialog.

- Mean stress and thickness corrections

are to be activated if the corresponding

parameters are to be applied in the Assign

Material dialog.

For more information on FKM mean stress correction, see the FKM section under Uniaxial S-N Fatigue.

- FE Model units are specified in this

dialog. The default unit specified is MPa.

Thickness reference will be automatically modified

based in the FE model unit selection.

Figure 3.

Fatigue Material

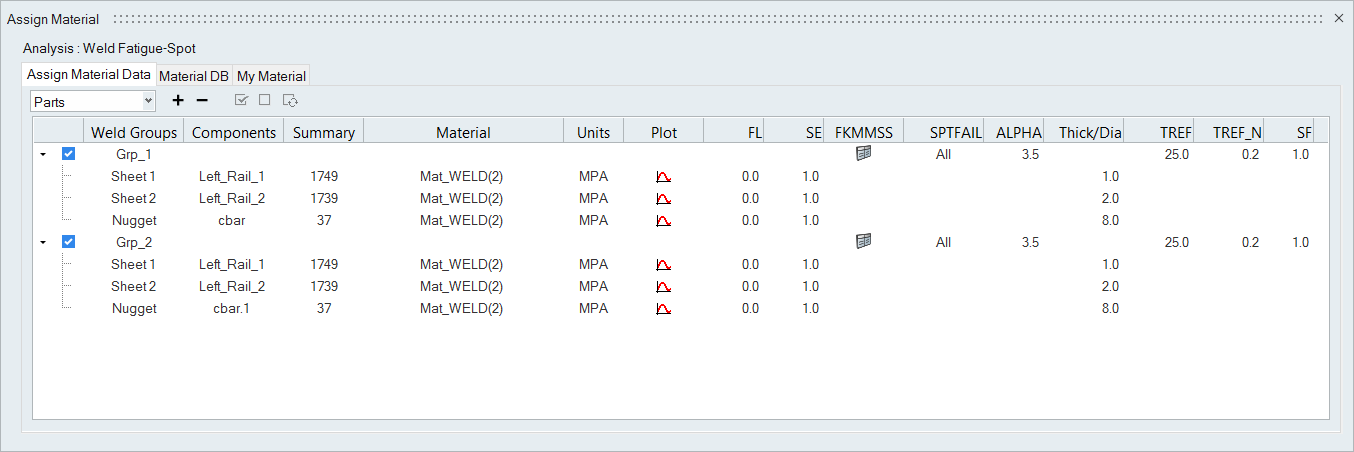

- The material properties (SN curve attributes for sheet 1, sheet 2, and the nugget) to be associated with the spot weld group are specified in the Assign Material dialog (SN attributes from the My Material or Material Database tab).

- The mean stress sensitivity value and the thickness correction values are specified in the Assign Material dialog.

- By default, the shell thickness of the sheets is referenced from the model. The sheets are editable in HyperLife.

- The spot weld diameter is to be specified in the Thick/Dia entry in the Assign Material dialog.

- TREF is set to 25mm by default, which is

equivalent to 1 inch, as specified by the

standard.

Figure 4.

Figure 4.

Fatigue Loads

- Similar to regular fatigue analysis, the fatigue loads are specified in the Load Map tool.

Output

Output for Spot Weld Fatigue Analysis is provided similar to regular Fatigue Analysis results. Damage and Life results for the SHEET, NUGGET, ALL or Auto are available based on the SPTFAIL selection in the Assign Material dialog. The damage calculation lists the worst damage if Auto is selected.