Sol2SPH Particle Behavior

All particles are created at the beginning of the calculation.

As long as their master element is not deleted, those particles are unreleased.

When the master solid element is deleted, the particles are released and behave like any other SPH genuine particle.

Unreleased particles kinematic is interpolated from their master element. In turn, the forces applied to those particles are transmitted to their corresponding solid nodes.

- Contact forces if they are slave of a TYPE7 interface or rigid walls

- Interaction forces with released particles or genuine particles.

Particle Activation Process

- Their master brick is deleted either because:

- The minimum time step has been reached (/DT/BRICK/DEL)

- The failure criteria associated to the brick material law has been met

- In case of contact:

- If an unreleased particle is slave of a TYPE7 interface and enters the gap of the master surface, the brick is deleted and the associated particles are released provided the Ibag flag of the interface is set to 1.

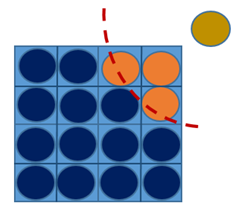

- If an unreleased particle is within interaction distance of any

particle belonging to a different part (including unreleased

particles), the master brick is deleted and the associated particles

are released. Therefore, no contact interface is required between

two Sol2SPH parts.

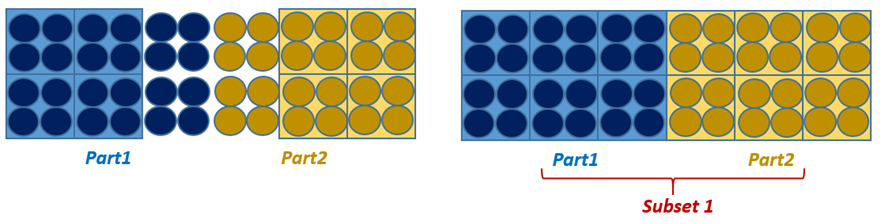

Figure 1. Orange Particles are Released as they are within Interaction Distance of the Yellow Particle. (which belongs to another part) - If Isol2sph is set to 2 in

/SPHGLO, then particles are not released if

the 2 parts belong to the same subset. This option can be useful to

prevent unwanted activation of particles at the junction of parts

belonging the same physical entities.

Figure 2. Isol2sph = 1: Unwanted particles activation / Isol2sph = 2 + subset definition

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/TYPE34/10

SPH prop example

# mp qa qb alpha_cs Skew_ID

2 0 0 0 0

# order h xi_stab

0 125.0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

The mass of the particles is automatically recalculated from the master element to ensure mass conservation. For this type of SPH part, the input mass may be 0.0.

- Smoothing length

- Size of the brick elements

- Number of particle per direction for each solid elements

The material law can be /MAT/LAW2, /MAT/LAW3, /MAT/LAW4, /MAT/LAW6, /MAT/LAW12, /MAT/LAW21, /MAT/LAW24, /MAT/LAW36, /MAT/LAW49, or /MAT/LAW81.

Both material laws for solid and SPH must be of the same type.

The material parameters can be different, but make sure there is consistency.

It is advised to keep the same parameters and change only the failure values (failure criteria, max strain, Spalling pressure, ...).