OS-T: 2020 Increasing Natural Frequencies of an Automotive Splash Shield with Ribs

In this tutorial you will generate a preliminary design of stiffeners in the form of ribs for an automotive splash shield. The objective is to increase the natural frequency of the first normal mode using topology to identify locations for ribs in the designable region.

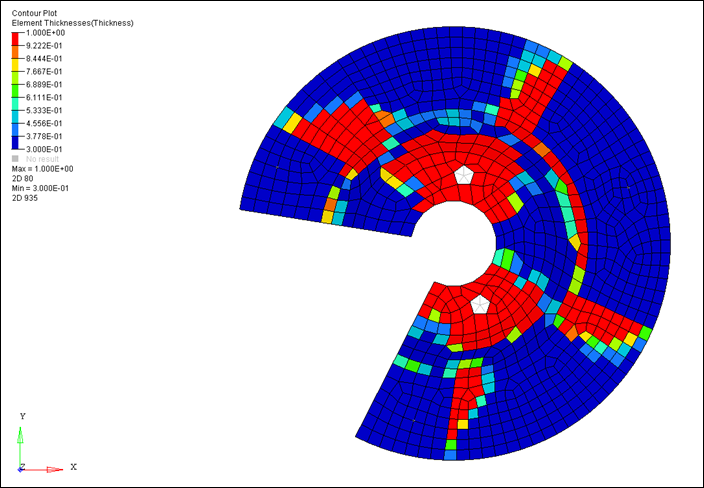

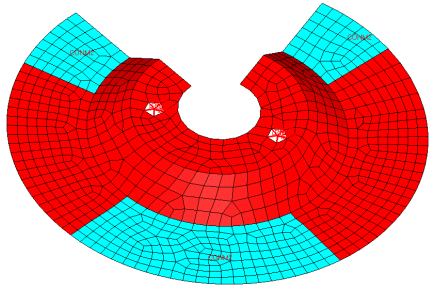

Figure 1. Finite Element Mesh. The finite element mesh contains designable (red) and non-designable (blue) material.

- Objective

- Maximize frequency of mode number 1.

- Constraint

- Upper bound constraint of 40% for the designable volume.

- Design Variables

- Density of each element in the design space.

Launching HyperMesh and Setting the OptiStruct User Profile

Importing the Model

Applying Loads and Boundary Conditions

Creating Load Collectors

Creating Constraints

Creating Load Steps

Submitting the Job

- sshield_analysis.html

- HTML report of the analysis, providing a summary of the problem formulation and the analysis results.

- sshield_analysis.out

- OptiStruct output file containing specific information on the file setup, the setup of your optimization problem, estimates for the amount of RAM and disk space required for the run, information for each of the optimization iterations, and compute time information. Review this file for warnings and errors.

- sshield_analysis.h3d

- HyperView binary results file.

- sshield_analysis.res

- HyperMesh binary results file.

- sshield_analysis.stat

- Summary, providing CPU information for each step during analysis process.

- sshield_analysis.mvw

- HyperView session file.

- sshield_analysis_frames.html

- HTML file used to post-process the .h3d with HyperView Player using a browser. It is linked with the _menu.html file.

- sshield_analysis_menu.html

- HTML file to post-process the .h3d with HyperView Player using a browser.

Viewing the Results

Setting Up the Optimization

Creating Topology Design Variables

Creating Optimization Responses

Defining the Objective Function

- Click the objective panel.

- Verify that max is selected.

- Click response= and select freq1.

- Using the loadsteps selector, select frequencies.

- Click create.

- Click return twice to exit the Optimization panel.

Defining Constraints

A response defined as the objective cannot be constrained. In this case, you cannot constrain the response freq1. An upper bound constraint needs to be defined for the response volfrac.

- Click dconstraints.

- In the constraint= field, enter volume_constr.

- Check the box next to upper bound, then enter 0.40.

- Click response = and select volfrac.

- Click create.

- Click return to return to the Optimization panel.

Running the Optimization

- sshield_optimization.mvw

- HyperView session file.

- sshield_optimization.HM.comp.cmf

- HyperMesh command file used to organize elements into components based on their density result values. This file is only used with OptiStruct topology optimization runs.

- sshield_optimization.out

- OptiStruct output file containing specific information on the file setup, the setup of the optimization problem, estimates for the amount of RAM and disk space required for the run, information for all optimization iterations, and compute time information. Review this file for warnings and errors that are flagged from processing the sshield_optimization.fem file.

- sshield_optimization.sh

- Shape file for the final iteration. It contains the material density, void size parameters and void orientation angle for each element in the analysis. This file may be used to restart a run.

- sshield_optimization.hgdata

- HyperGraph file containing data for the objective function, percent constraint violations, and constraint for each iteration.

- sshield_optimization.oss

- OSSmooth file with a default density threshold of 0.3. You may edit the parameters in the file to obtain the desired results.

- sshield_optimization.stat

- Contains information about the CPU time used for the complete run and also the break-up of the CPU time for reading the input deck, assembly, analysis, convergence, and so on.

- sshield_optimization.his_data

- The OptiStruct history file containing iteration number, objective function values and percent of constraint violation for each iteration.

- sshield_optimization.HM.ent.cmf

- HyperMesh command file used to organize elements into entity sets based on their density result values. This file is only used with OptiStruct topology optimization runs.

- sshield_optimization.html

- HTML report of the optimization, giving a summary of the problem formulation and the results from the final iteration.

- sshield_optimization_frame.html

- HTML file used to post-process the .h3d with HyperView Player using a browser. It is linked with the _menu.html file.

- sshield_optimization_menu.html

- HTML file used to post-process the .h3d with HyperView Player using a browser.

- sshield_optimization_des.H3D

- HyperView binary results file that contains: Density results from topology optimizations, Shape results from topography or shape optimizations and Thickness results from size and topology optimizations.

- sshield_optimization_s1.H3D

- HyperView binary results file that contains: Displacement results from linear static analysis, Element strain energy results from normal mode analysis and Stress results from linear static analysis, etc.

Viewing the Results

Setting Up the Final Normal Modes Analysis

Deleting the Current Model

Importing the Model

Submitting the Job

- sshield_newdesign.html

- HTML report of the analysis, providing a summary of the problem formulation and the analysis results.

- sshield_newdesign.out

- OptiStruct output file containing specific information on the file setup, the setup of your optimization problem, estimates for the amount of RAM and disk space required for the run, information for each of the optimization iterations, and compute time information. Review this file for warnings and errors.

- sshield_newdesign.h3d

- HyperView binary results file.

- sshield_newdesign.res

- HyperMesh binary results file.

- sshield_newdesign.stat

- Summary, providing CPU information for each step during analysis process.

- sshield_newdesign.mvw

- HyperView session file.

- sshield_newdesign_frames.html

- HTML file used to post-process the .h3d with HyperView Player using a browser. It is linked with the _menu.html file.

- sshield_newdesign_menu.html

- HTML file to post-process the .h3d with HyperView Player using a browser.

Viewing the Results

Comparing Results

What is the percentage increase in frequency for your first mode (sshield_analysis.fem vs. sshield_newdesign)?

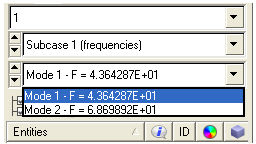

You have seen that the frequency of the structure for the first mode has increased from 43.63 Hz to 84.88 Hz.

How much mass has been added to the part (check the mass of your ribs in the mass calc panel in the Tool page)?

What is the percentage increase in mass?

.

.

(Modal).

(Modal).

to open the Deformed panel.

to open the Deformed panel. .

. to start the animation.

to start the animation. to stop the animation.

to stop the animation.

to open

the

to open

the