Phase 3: Ply Stacking Sequence Optimization

This algorithm is aimed at providing a global view of what the optimal stacking sequence could be. An input deck for the ply stacking sequence optimization, oht_opti_ph2_shuffling.*.fem, was generated from a previous design stage.

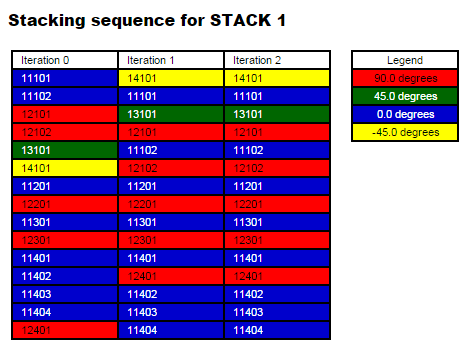

Each ply bundle is divided into multiple PLYs whose thickness is equal to the manufacturable thickness (0.01 in this case), and the STACK card is updated accordingly. In this design phase, composite plies are shuffled to determine the optimal stacking sequence.

- The maximum successive number of plies of a particular orientation does not exceed 4 plies.

- The outermost four layers of the layup must be -45, 0, 45, 90.

Importing the Model

Saving the Database

- From the menu bar, click .

- In the Save As dialog, enter oht_opti_ph3.hm for the file name and save it to your working directory.

Updating the Design Variables

Running the Optimization

- oht_opti_ph3.prop

- OptiStruct property output file containing all updated property data from the last iteration for size optimization.

- oht_opti_ph3.shuf.html

- An HTML file contains the history of the shuffling optimization and the view of the ply stacking sequence.

Post-processing Results

The plies are color coded based on their fiber orientations. The columns represent the global trend of the ply stacking sequence at a particular iteration, with the last column being the final solution.

The weight of the part has not been changed during the shuffling design phase, rather the plies were reordered to obtain the maximum performance.

Figure 1. Shuffling Optimization History

.

.