Creating the MBD Model of the Car Door

In this step, you will create the MBD model of the car door, after which the door closure simulation can be performed.

For this model, use the following units for length, mass, force, and time, respectively: millimeter, megagram, Newton, second.

Model Units

Points

For building this model, a total of six points need to be created.

Figure 1. Points Required for the Model

Bodies

In this model, there are two bodies: one body to represent the car and another to represent the flexible door.

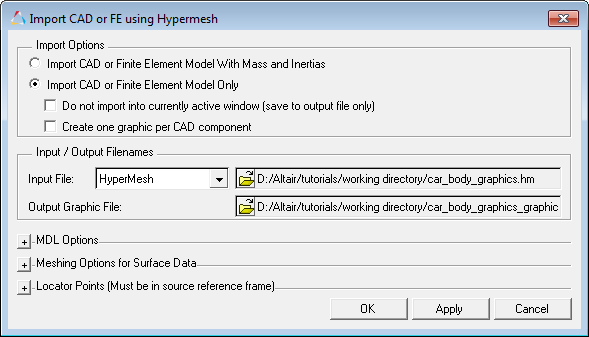

Graphics

After Point 6 above, you can see that the Door Body has a graphical representation, but Car Body does not. You can add a file graphic to the Car Body so that visualization of the model becomes more meaningful.

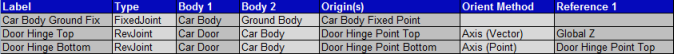

Joints

For this body, you will need to add a total of four constraints/joints. One of these joints will need to be added using the XML template.

Initial Conditions

In this simulation, body initial velocity will act as the primary motion input to the model.

Markers

To represent the locking mechanism of the car door, you will use a sensor activated fixed joint between the Car Body and the Door Body that initially is deactivated. The fixed joint will need to be created using XML templates since the MotionView interface allows joints to be created using bodies and points. In this case, you need to create the joint between two initially non-coincident markers.

Sensors

In this model, you will use an Event Sensor to detect the closing of the door. At the instance of the event detection, the fixed joint between the door and the car body is activated to simulate the actual locking mechanism.

Templates

To simulate the door lock, you need a fixed joint between the door and the car body. The fixed joint needs to be activated with the sensor. The activation of the joint and the deactivation of the sensor can be done using a sequential simulation operation.